47 Higher Cadewell Lane , Torquay , Devon ,TQ2 7EX United Kingdom

Reg Number 06591353 (United Kingdom) VAT number 915 2781 21

tel.+44 (0)1803 400950

tel.+44 (0) 1803 663813

Special Projects...

By a continued policy of Research and Development, Conbar keeps ahead with new Technology, actively pursuing an "in-house" programme of technological research.

Some examples of "firsts" in technology (at the time) are:-

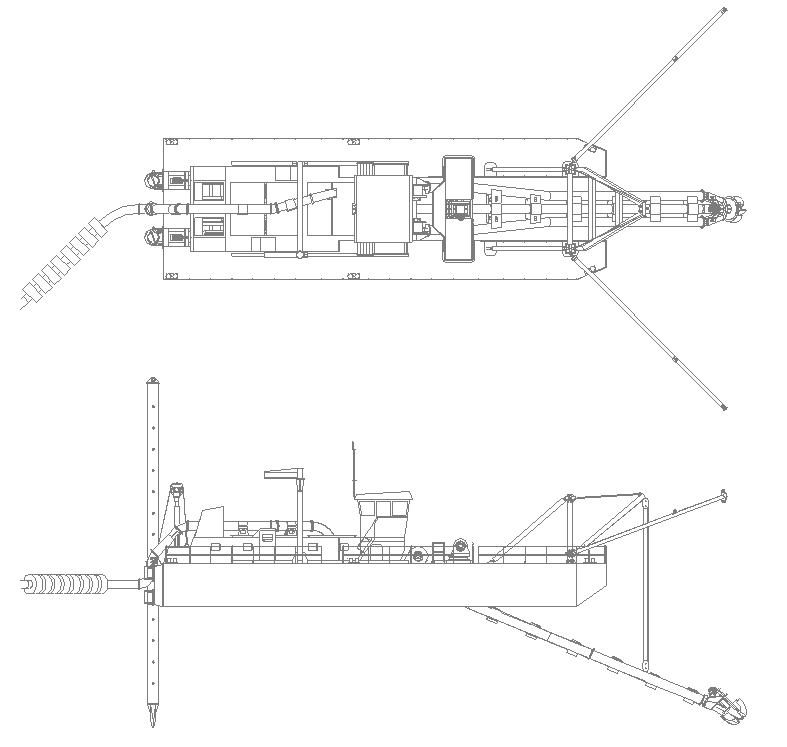

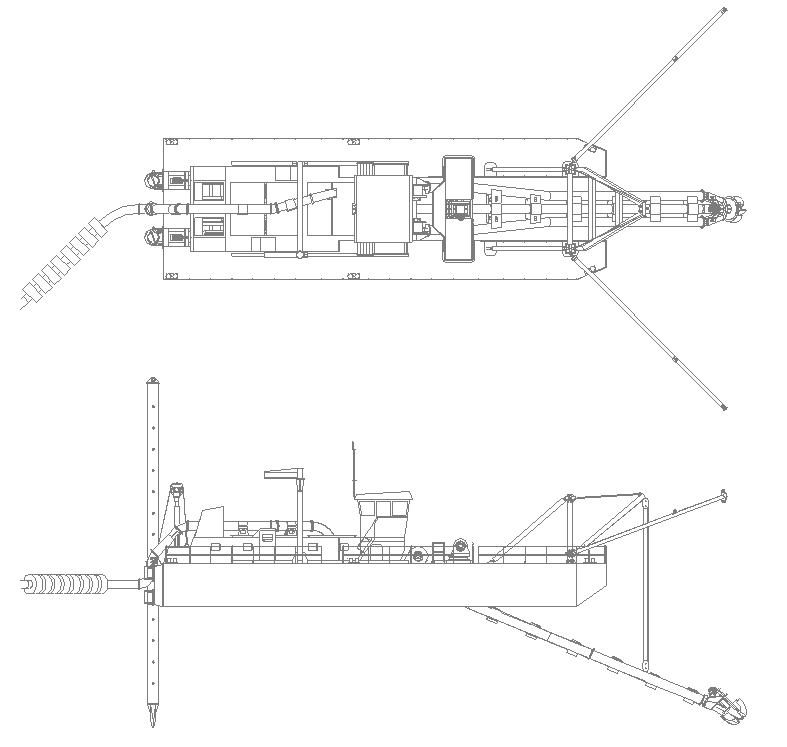

Trenching machine

this machine was designed and builtin the UK and

trenched between the Java -Madura Straits in Indonesia,

for simultaneous laying & burying of

power cables.

For details please roll over image.

|

Hover Dredger

The World's first !

For further details please roll over image

|

Environmental

dredger

capable of removing siltation

at up to 85 - 95% concentration

For details please roll over image

The Port Frederick

Designed in the UK and Built inTasmania,Australia, multi purpose

Trailing Suction Hopper Dredger,

oil skimmer andfire-fighting vessel.

For details please roll over image.

|

THE HOVER DREDGER

A DELELOPEMENT OF THE STANDARD CUTTER SUCTION DREDGER BUT WITH THE ADDITION OF SKIRTS AND DIESEL ENGINE POWERED LIFT FANS -DESIGNED & BUILT FOR 'MACKLEY CONSTRUCTION LTD' IN THE MID 70'S.

The approach to the site was over mud flats, making access difficult, hence the hover design, which allowed the dredger to skirt over the mud flats and due to air cooled engines the dredging time was not dependant on the tide.

The Environmental Dredger

is so named because it is eminently suitable for dredging contaminated siltation and other pollutions which affect the environment. With environmental concerns at the forefront and heart of the future of dredging, the environmental dredger provides a cost effective and efficient solution to environmental problems.

It was developed through extensive research and trials in Venice, Italy, and it was found that a concentration of up to 90% of solids could be removed, thus making the system ideal for the removal of siltation from lakes, rivers, harbours etc.

•Material can be pumped almost insitu into containers for treatment

•One man operation of dredger

•No winch wires required - easier dredging

•Self propelled

•Automatic adjusting

•Environmentally acceptable in confined places

•Reservoir desilting with minimum water removal

•Canal cleaning (unless heavily dumped, in which case combined machines may be required)

•Able to work in less than 0.8m of water

•Running costs less than any other known system of dredging

Does not need winches

Ideal for tight situations, e.g. canals, Marinas, Ports, where winches hinder other traffic and manoeuvrability.

No need to re-accommodate craft in Marina whilst cleaning up

Cost savings, less inconvenience for craft owners

Has its own propulsion units

No need for tug boat or workboat. Gives increased manoeuvrability

Save on cost of workboat and on cost of manpower to operate same

Has a low draft, and no Spuds, and uses thrusters to stay in position

Easier access to places at low water, means continuity of operation

Increased productivity

Port Frederick

Not just a Trailing Suction Hopper Dredger .....

This unique vessel was originally designed to eliminate the need for numerous, and often unused, vessels in the port. Despite its size, it had complete manoeuvrability in the harbour and restricted waterways due to twin 360 degree steerable Aquamaster propulsion units and a 360 degree steerable Aquamaster bow thruster.

Built originally for the Port of Devonport Authority,Tasmainia, It has now gone into private ownership and is operated by McQuade Marine, who use the vessel to undertake various dredging operations around Austraila and New Zealand.

Used for:

Maintenance Dredging

Fire fighting for port

Sand and gravel dredging for construction industry

Oil pollution skimmers

With a length of 160 ft x 40 ft beam, she was modular constructed on a slipway in Devonport, Tasmainia, Australia.

Speed 8 knots (loaded)

Bollard pull of 16 tons

Trenching Operation in Indonesia

Trials in Falmouth UK

....Preparing to go deeper....

contact |© Conbar UK LTD 2019